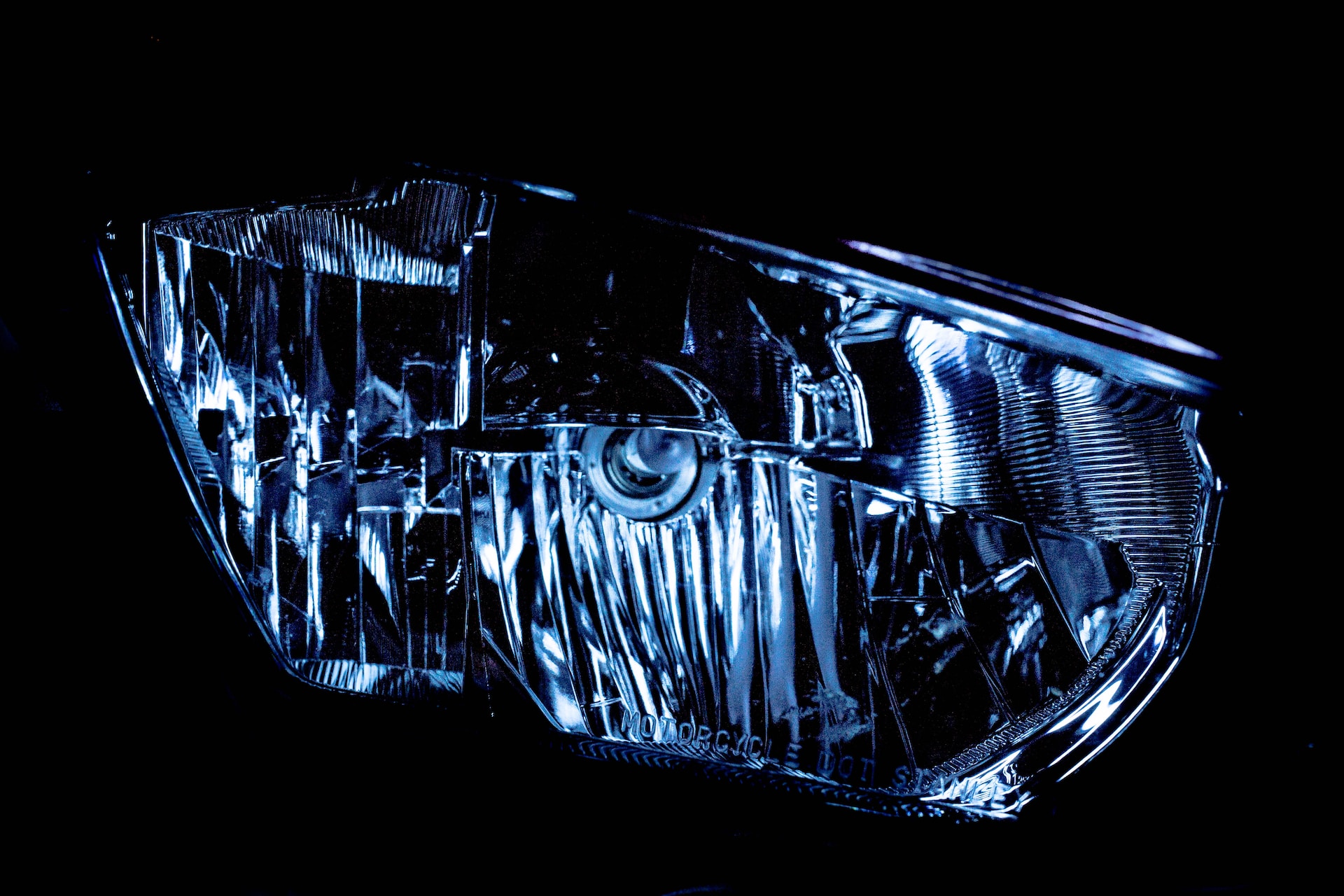

Plexiglass headlights were very popular on cars in the 90s. However, over time they can become dull, yellowed or scratched, which can detract from the aesthetics of the vehicle. Fortunately, there are restoration techniques that can restore all their splendor to these Plexiglas headlights.

Why do plexiglass headlights deteriorate?

The plexiglass headlights of 90s cars are exposed to the elements, UV rays from the sun, air pollution and chemical splashes on the road. All of these can cause premature aging of the material, resulting in discoloration and loss of transparency.

The different stages of restoring plexiglass headlights

Restoring Plexiglas headlights can be done at home, with a few specific tools and products. Here are the steps to follow to bring those tarnished headlights back to life:

- Cleaning : Start by cleaning the headlights thoroughly using soapy water and a soft sponge. Remove all the dirt, bugs and residue that has built up over time.

- Sanding : Use fine-grit sandpaper to sand the headlights using circular motions. This step helps remove scratches and surface imperfections.

- Polishing : Apply a specific polishing product for plexiglass headlights to a foam polishing pad. Use circular movements until the headlights return to their original shine.

- Protection : To prevent future dulling of headlights, apply a protective product specifically designed for plexiglass headlights. This product will form a protective layer that will prevent damage from UV rays and weather.

The benefits of restoring plexiglass headlights

Restoring plexiglass headlights has many advantages. First of all, it improves the aesthetics of the car by making it look fresher and more attractive. In addition, headlights in good condition guarantee better visibility at night, which contributes to road safety.

Mistakes to avoid when restoring plexiglass headlights

It is important to mention some common mistakes to avoid when restoring plexiglass headlights. First of all, it is crucial not to use abrasive products like sandpaper that are too rough, as this could permanently damage the headlight surface. Additionally, it is recommended to carefully follow the instructions for the restorative and protective products used.

The economic and environmental impact of restoring Plexiglas headlights

In a context where sustainability and the circular economy are gaining importance, restoring rather than replacing is becoming a major concern for consumers and manufacturers. Restoration of plexiglass headlights is part of this approach and presents a significant economic and environmental advantage.

Financial economics : Replacing a headlight can be expensive, especially when you take into account the price of the part, labor and possibly recalibration of the lighting system. By opting for restoration, car owners can make significant savings.

Reduction of the ecological footprint : Producing a new lighthouse requires resources, generates carbon emissions during manufacturing and logistics, and generates waste. By choosing to restore, we limit the consumption of resources, we reduce emissions and we reduce the volume of waste.

Resource preservation : Plexiglas, like many materials, comes from non-renewable resources. Restoration extends its lifespan and therefore delays the need to produce more.

Enhancement of the local economy : Rather than buying a product that could have been manufactured on the other side of the world, calling on a local professional to restore your headlights helps support the local economy.

However, to maximize these benefits, it is essential to use environmentally friendly restoration products and to favor gentle techniques that preserve the original quality of the lighthouse.

Sustainable alternatives for car headlights

While restoring plexiglass headlights is a beneficial solution to extend their lifespan, it is also wise to consider the sustainable alternatives available on the market. These alternatives aim not only to address aesthetic and functional concerns, but also to offer a more environmentally friendly option.

Eco-designed materials : Some manufacturers are now exploring the use of recycled or biodegradable materials for headlight manufacturing. Although more expensive, these materials have the advantage of reducing the environmental impact throughout the product life cycle.

Low consumption lighting systems : Lighting technologies such as LEDs and OLEDs use less energy and have a longer lifespan than traditional bulbs. In addition to reducing energy consumption, these systems require less maintenance and replacement.

Eco-responsible production techniques : In addition to the choice of materials, the way in which headlights are manufactured plays a crucial role in their ecological footprint. Manufacturing processes that use less water, energy and generate less waste can make a significant difference.

Education and awareness : To encourage the adoption of these alternatives, it is crucial to inform consumers about the benefits and environmental implications of their choices. This can involve information campaigns, workshops or even tax incentives for those who opt for more ecological solutions.

Impact of plexiglass headlights on the environment

While the restoration of plexiglass headlights is well documented, the environmental impact of these elements, when they are not properly treated at the end of their life cycle, is less often discussed. Understanding this impact allows us to understand the importance of their maintenance and the search for more sustainable alternatives.

Plexiglas headlights and the waste problem

When discarded, Plexiglas headlights often end up in landfills, where they will take several decades to decompose, if not longer. Unlike other types of plastic waste, plexiglass is not easily recyclable due to its specific properties. This makes it a significant contributor to the plastic waste that pollutes our environment.

Resource consumption

The production of plexiglass headlights requires the use of non-renewable resources, such as petroproducts. Each lighthouse manufactured therefore contributes to the depletion of these precious resources.

The hidden cost of transport

Headlights are often produced in factories far from places of sale or car assembly centers. Their transport therefore generates carbon emissions, which could be reduced if production were localized or if lighter materials were used.

The quest for solutions for a greener industry

Faced with these environmental challenges, several initiatives are emerging to make the plexiglass headlight industry greener:

- Improved recycling : Research is underway to find effective recycling methods for Plexiglas headlights, making it possible to reduce the volume of waste.

- Eco-responsible design : Considering the end of life of a product from its design is essential. Designs that facilitate disassembly and separation of components can help better recycle end-of-life headlights.

- Consumer awareness : It is vital that car owners are aware of the environmental impact of their perspex headlights and are encouraged to opt for restoration solutions rather than replacement.